More details on the process yesterday:

Removed side cement boards to have more room to put upper back piece in. Shims would not stay in place, board kept slipping around & we couldn't get proper gap with a screw in the corner. I finally suggested popping screws in to hold the bottom edge of the top board at the right height and keep it pressed flush against the wall. That allowed us to keep it in place to put in screws.

Put the side boards back in place-- shimming to make them level. Dry fit the surround to mark where to cut. Discovered that it fit together nicely enough without any shimming (the instructions said not to leave any gaps). Marked where to cut cementboards.

Removed the side cement board panels to cut them with the scoring tool. Cut the top cement board in place. Did another dry fit of the surround to check the fit again and make sure things fit. Marked for adjustments to cuts.

While my friend was taking a breather & talking to my brother, I took the cement boards down, set them aside, vacuumed with the shopvac and cleaned the tub edge and flange with alcohol (leaves no residue and dries faster). Friend was surprised when he came back in.

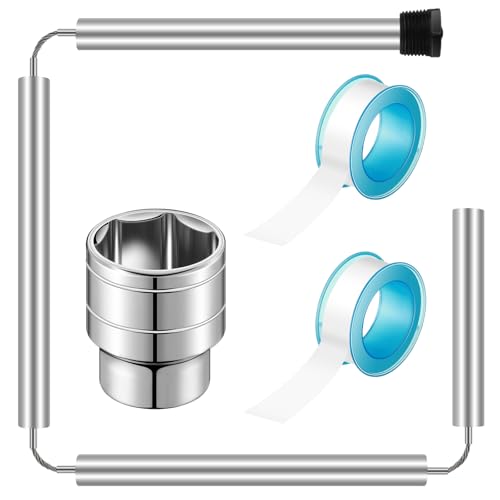

Put up plastic sheathing along with waterproof gorilla tape-- that stuff stays in place really well. Couldn't find 3rd roll of tape I bought so ended up not taping the bottom. I will seal it with auquadefense & caulk. I still wanted to tape with something but friend wasn't up to it and I suck at trying to apply anything adhesive. He actually had me stay away from the tape because he said I jinx adhesives. LOL. I did help hold the plastic up in one corner and jinxed it-- tape stuck to something it shouldn't and would not come off. LOL. But it ended up being ok. As an aside, I told him exactly how many slats & popsicle sticks were needed for the back wall lower cement board. He didn't believe me until he kept checking the level and I handed him more of the things. He laughed and said I was right we got things tightened down. While the cementboards were down I did some cleanup to some rough edges. The aquadefense had a big drip on the bottom right corner of the back board so I trimmed that off.

Anyway, I don't remember if it was before or after the next dry fit of the panels, but while friend was taking another breather I put in more screws to secure the back lower board. We did both take breaks but I went back to working on stuff before he did. He was doing more of the lifting and more exhausting stuff in general. On the dry fit we discovered that the side edge on the left board needed to be trimmed back a bit more. Also trimmed above the surround on both sides, but the scoring tool wasn't cutting it so I brought out the oscillating tool. It is slow going through wood but it went through cementboard like a champ. I forgot to mention that when my friend was putting in screws for the cementboards I was handing them to him to make the process faster. I also had to pop a battery out to charge it and put in another battery. 2nd battery ran out of juice but 1st battery had charged by that time (I have a rapid charger).

After cutting the cementboards we needed to adjust some screw placements.

Last dry fit of the wall panels looks good.

I despise tile so there will be no tile in this bathroom. LOL. I forgot to take pictures of my drawings & writing inside the wall. Also forgot to drop a bottle with a note. We were going to take the panels down again so I could put on aquadefense but I didn't want to mess with leveling everything again and will just be doing aquadefense while everything is in place. I'm going to put 5-1/2" tall PVC trim above the surround. I'll probably need my friend's help to put it up since my left arm still can't reach high enough with my left arm. I've come to like the blue stripe look of the old wall panels. I may find some non-yellowing clearcoat to paint over it for extra protection though.

Next steps:

- Set wallset aside

- Clean up tub

- Trim plastic sheet at bottom

- Drill small holes from inside closet for tub spout, controls, & shower arm

- Apply Aquadefense to seams & edges.

- Apply alkalai resistant mesh tape & L-bead trim to edges

- Apply thinset to tape & trim

- Put low expansion foam inside back of shelf for back wall panel

- Measure hole locations to know where to avoid putting adhesive for wall surround

- Put up wall surround & do small sort of pilot holes from closet side to know where to drill for controls & tub spout (shower arm will be above cement board & wallset)

- Install PVC trim

- Drill from surround side and cleanup any rough edges

- Small amount of caulk will be put inside holes where surround meets cementboard to seal them up (alternatively, I can use aquadefense there after the wall surround is installed but will have to make sure there are no drips)

- Install plumbing and shower trim (after making sure the waterlines are clear of debris/dirt)

- Install showerhead

- Put up curtain rod and curtain

- Take a shower

Not all of those are in order.

Here are the most recent pics I took. I'll get more later. The back wall panel had been in a plastic bag. The right wall panel wasn't wrapped. The left wall panel had protective plastic on the back and edges but not the front. The videos and descriptions all indicated that the cling plastic was supposed to cover the fronts of all of them. The back panel had a sticker I removed but it left adhesive behind so I will have to clean that up later (I just now remembered that).

I cut and did a test-fit of the L-bead trim on the right side. Looks nice. I may leave the tearaway strip and just caulk it to the edge of the surround very carefully. Or use doublesided sticky tape or something to make it stay in place. I'll have to see how it looks when I dry fit the PVC trim boards. If it looks bad I'll tear it away. (I put tape on the trim to hold it in place)

I cut off about 58" from a 10' piece. That leaves a little over 5' left and I'm trying to decide where to use it--

horizontally on back wall

vertically on left wall

Cut in half and used horizontally on the tops of both sides. I bought enough to cover them all and to cover that wall corner that looks ugly where the wood paneling doesn't quite meet up. Although, I might try to find a tall PVC outer corner trim piece for that instead. I'm going to add wainscoting to the lower part that is painted white.