Thanks, Blueskyhigh. This project has been quite the journey. I'm really hoping to have it done by next week if possible. I'm ready to apply thinset but I'm trying to figure out the ratio of water to powder since I won't be using the entire bag. The only size available was 50lbs and man, did my back complain when I carried that thing in. LOL. I set it on the side of the tub for now but will have to move it out of the way to put down plastic and protect the floor & tub. I've decided I'm going to build the thinset out a bit more on the right side where the board sunk in so the wall will be plumb. I will cram the stuff in with my hands if I have to. LOL.

This is how it looks with trim up:

These are the instructions for the thinset:

1. Into a clean mixing container, pour the following amounts of clean water according to the bag sizes indicated: For a 25-lb. (11,3-kg) bag: About 2.5 to 3 U.S. qts. (2,37 to 2,84 L) of water For a 50-lb. (22,7-kg) bag: About 5 to 6 U.S. qts. (4,73 to 5,68 L) of water

2. Gradually add the appropriate amount of powder while slowly mixing, using an electric drill with an angled cross-blade mixer or double-box mixer.

I know a quart is 4 cups. I need to figure out how to convert the weight of the mix to cups. I know with Portland cement it's like 1lb = 1.27 cups (I found a calculator/conversion chart) but I don't know about this stuff. My brain is not wanting to do the math. I'm worried that if I do the mix until it looks right method that it might set up too fast to work with.

Oh wait... I just found a Q&A where they said "

4 parts powder to one part water mix ratio" after making sure to mix the powder up so the polymers are evenly distributed. 10 to 20 min work time. Woohoo. (I'm bolding that so I remind myself). I know hard water made the leveling mix set faster so I might use filtered water and put it in the fridge. Cold water gives more working time. I think I will put a cap on the bucket while I'm spreading stuff.

Gonna have to shake that bag like shake & bake. LOL. I was feeling like a complete wuss when I was moving the bag bc I thought it was only 25lbs but then I saw I got 50lbs and felt a little less wussy.

I think I'm going to start out with 4 cups of water and 16 cups of powder. If I use it up, I can mix more.

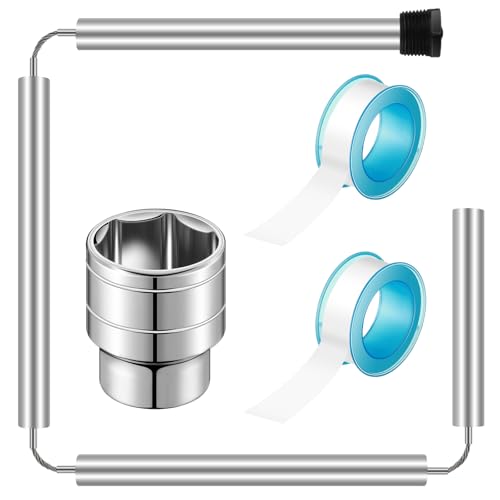

Now I need to organize all my stuff, make sure I have ALL of the tools I need, put on a painter's suit, spread plastic and tape all over to protect the floor & tub.

Lis of things:

- Coveralls (I might have some somewhere already)

- Gloves

- Tape

- Plastic covering

- Wet measuring cup

- Dry measuring cup

- Small bucket to separate powder to pour in to water

- Mixing attachment for drill

- Paint stirring stick (have plenty)

- Trowels/taping knifes for spreading thinset

- Scoop thingy for getting thinset/mud out of bucket

- Extra water (in case mix needs more and to clean tools)

- Bottled water (to keep me hydrated)

- 5 gallon bucket w/ lid

- Cheap sponge to wipe stuff

- Paper towels

- A working spine & brain

Anything I'm missing? Any advice?

Is spreading thinset pretty much the same as spreading drywall "mud" for the purpose of sealing tape and stuff? I think I will start with the left wall first-- starting at the top-- and then work my way to the right. I don't care if the stuff is perfect so long as it seals the tape on. The back and edges of the surround panels have ridges, the corners of the surround are curved so small bumps/imperfections won't matter.

Edit because I forgot to mention that I marked the back of the right surround panel where the holes will go so I know to not put adhesive there. Unfortunately the controls will be smack in the middle of some of the ridges-- but that might just mean that area has better reinforcement so it may work out better that way. I'm probably going to make a foam board mockup of the hole for the controls to cover the area on the board when I'm applying thinset. I'll mark a circle around the tub spout hole too. Gonna go do that in a few min.