For more detailed info on my setup: Float lever sticking & power to jet pump problem

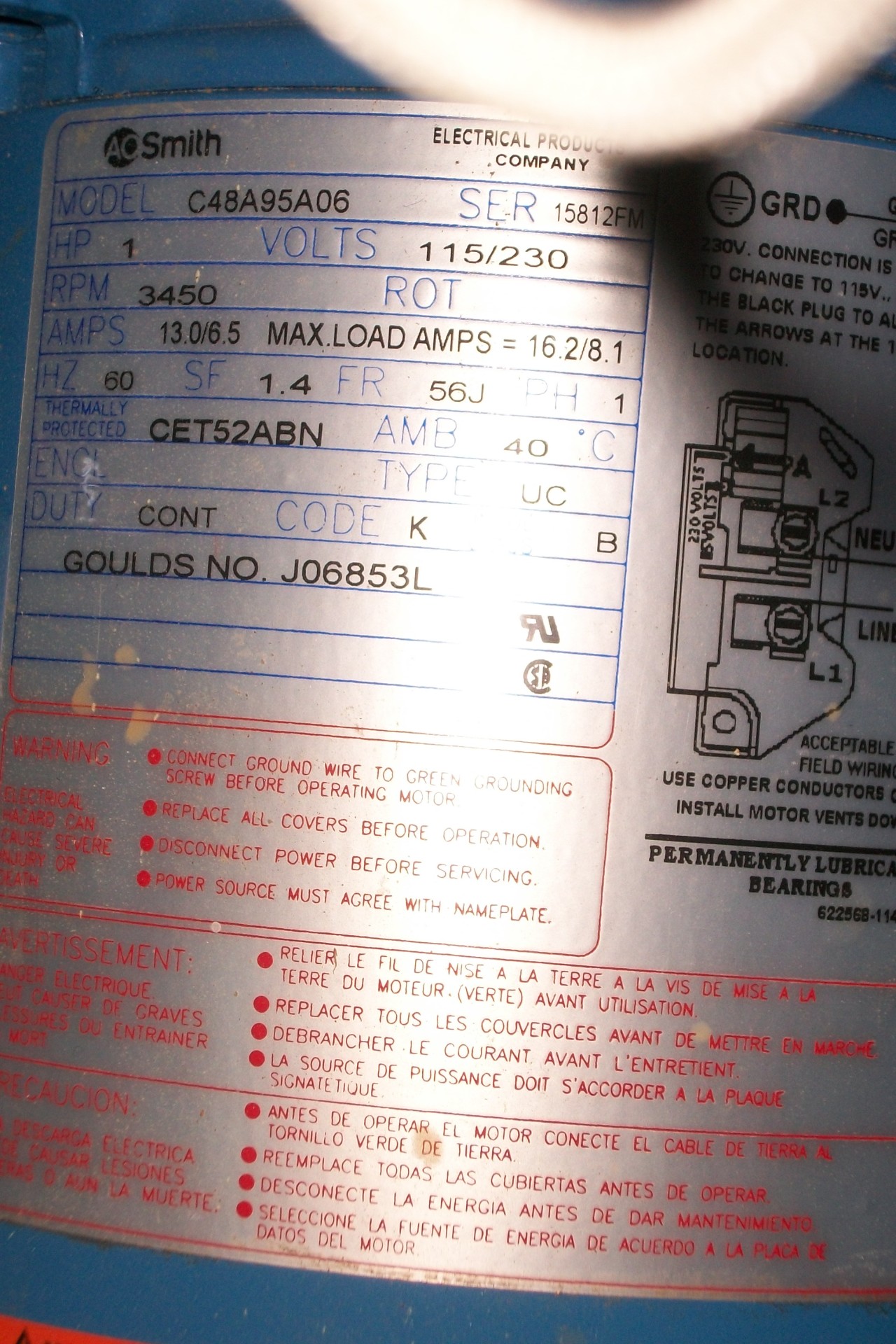

I have a Gould's Jet pump

It's a shallow well 1HP pump.

It has a 50/30 pressure switch (I hope that is the correct one). For some reason the switch keeps burning out. Had to replace it at least 3 times in the last year. There have been some major power surges & wires got fried a couple times, but this time the wires were undamaged & I'm not sure if it was a power surge that caused it. It used to sense when the water level in the cistern was low so it didn't try to pump but it doesn't do that anymore. Cistern's float switch got jammed (have since adjusted it to prevent that).

I patched a hole in the roof of the shed where it was leaking directly over the float switch & I patched a few other holes in the roof in different spots. Wires were dry, but when my friend took the cover off the jet pump's pressure switch, it was burnt. I don't know if the switch is just lousy (been getting them from Tractor Supply) or if there is an electrical problem.

Someone in the store suggested the foot valve at the bottom of the well could be causing a problem. I don't even know if it has a foot valve.

We just replaced the switch again. Last one was replaced about a month ago after two hurricanes. Am I using the wrong pressure switch? Should I get the 40/60 one instead?

I knew the switch was going bad because it was "chattering". Would hum on and then make a loud click as it shut off and on several times. It would run for a few seconds then click off then back on and then rapidly on and off.

Could it be that the pressure tank is bad or going bad?

So, any ideas on what the problem could be or how to prevent it from recurring? It seems to coincide with storms. It happened after the power blinked out for a few seconds during the rain.

I have a Gould's Jet pump

It's a shallow well 1HP pump.

It has a 50/30 pressure switch (I hope that is the correct one). For some reason the switch keeps burning out. Had to replace it at least 3 times in the last year. There have been some major power surges & wires got fried a couple times, but this time the wires were undamaged & I'm not sure if it was a power surge that caused it. It used to sense when the water level in the cistern was low so it didn't try to pump but it doesn't do that anymore. Cistern's float switch got jammed (have since adjusted it to prevent that).

I patched a hole in the roof of the shed where it was leaking directly over the float switch & I patched a few other holes in the roof in different spots. Wires were dry, but when my friend took the cover off the jet pump's pressure switch, it was burnt. I don't know if the switch is just lousy (been getting them from Tractor Supply) or if there is an electrical problem.

Someone in the store suggested the foot valve at the bottom of the well could be causing a problem. I don't even know if it has a foot valve.

We just replaced the switch again. Last one was replaced about a month ago after two hurricanes. Am I using the wrong pressure switch? Should I get the 40/60 one instead?

I knew the switch was going bad because it was "chattering". Would hum on and then make a loud click as it shut off and on several times. It would run for a few seconds then click off then back on and then rapidly on and off.

Could it be that the pressure tank is bad or going bad?

So, any ideas on what the problem could be or how to prevent it from recurring? It seems to coincide with storms. It happened after the power blinked out for a few seconds during the rain.

![MEISTERFAKTUR drain snake 2.0 [50 FT] - with drill attachment - Ideal plumbing snake for sink and drain unblocking - Solid drain auger for real DYIs! (50 FT - 1/4 inch)](https://m.media-amazon.com/images/I/41VwmTiOsgL._SL500_.jpg)