This is for a new piping system to feed propane (LP) to a new gas stove in the State of Connecticut which is governed by International Residential Code 2015 (IRC 2015).

According to "G2421.2 (410.2) MP Regulators":

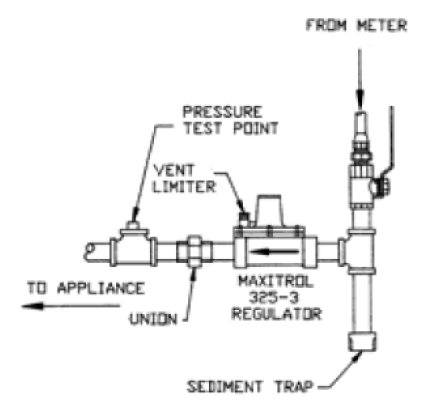

5. A tee fitting with one opening capped or plugged shall be installed between the MP regulator and its upstream shutoff valve. Such tee fitting shall be positioned to allow connection of a pressure-measuring instrument and to serve as a sediment trap.

6. A tee fitting with one opening capped or plugged shall be installed not less than 10 pipe diameters downstream of the MP regulator outlet. Such tee fitting shall be positioned to allow connection of a pressure-measuring instrument.

7. Where connected to rigid piping, a union shall be installed within 1 foot (304 mm) of either side of the MP regulator.

This corresponds to a setup like this:

My first question is what the heck is the purpose of the union and why do they require it?

If I add a gauge and several PSI of air to the test point, that will expose the regulator outlet to high pressure and is apparently a no-no, and pressure testing a valve is also apparently a no-no. So am I to guess that I somehow have to open and cap the union?

What about pressure testing the sediment trap, just soapy water under load?

According to "G2421.2 (410.2) MP Regulators":

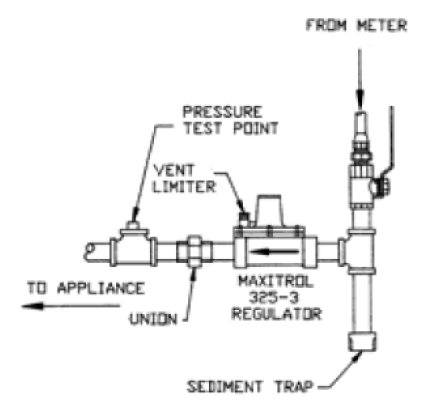

5. A tee fitting with one opening capped or plugged shall be installed between the MP regulator and its upstream shutoff valve. Such tee fitting shall be positioned to allow connection of a pressure-measuring instrument and to serve as a sediment trap.

6. A tee fitting with one opening capped or plugged shall be installed not less than 10 pipe diameters downstream of the MP regulator outlet. Such tee fitting shall be positioned to allow connection of a pressure-measuring instrument.

7. Where connected to rigid piping, a union shall be installed within 1 foot (304 mm) of either side of the MP regulator.

This corresponds to a setup like this:

My first question is what the heck is the purpose of the union and why do they require it?

If I add a gauge and several PSI of air to the test point, that will expose the regulator outlet to high pressure and is apparently a no-no, and pressure testing a valve is also apparently a no-no. So am I to guess that I somehow have to open and cap the union?

What about pressure testing the sediment trap, just soapy water under load?