- Joined

- Sep 28, 2014

- Messages

- 8,578

- Reaction score

- 2,977

Ok, I agree that sounds faster as well, I will go with the tee/nipple method. I'll probably get the stainless corrugated since they bend a little easier.

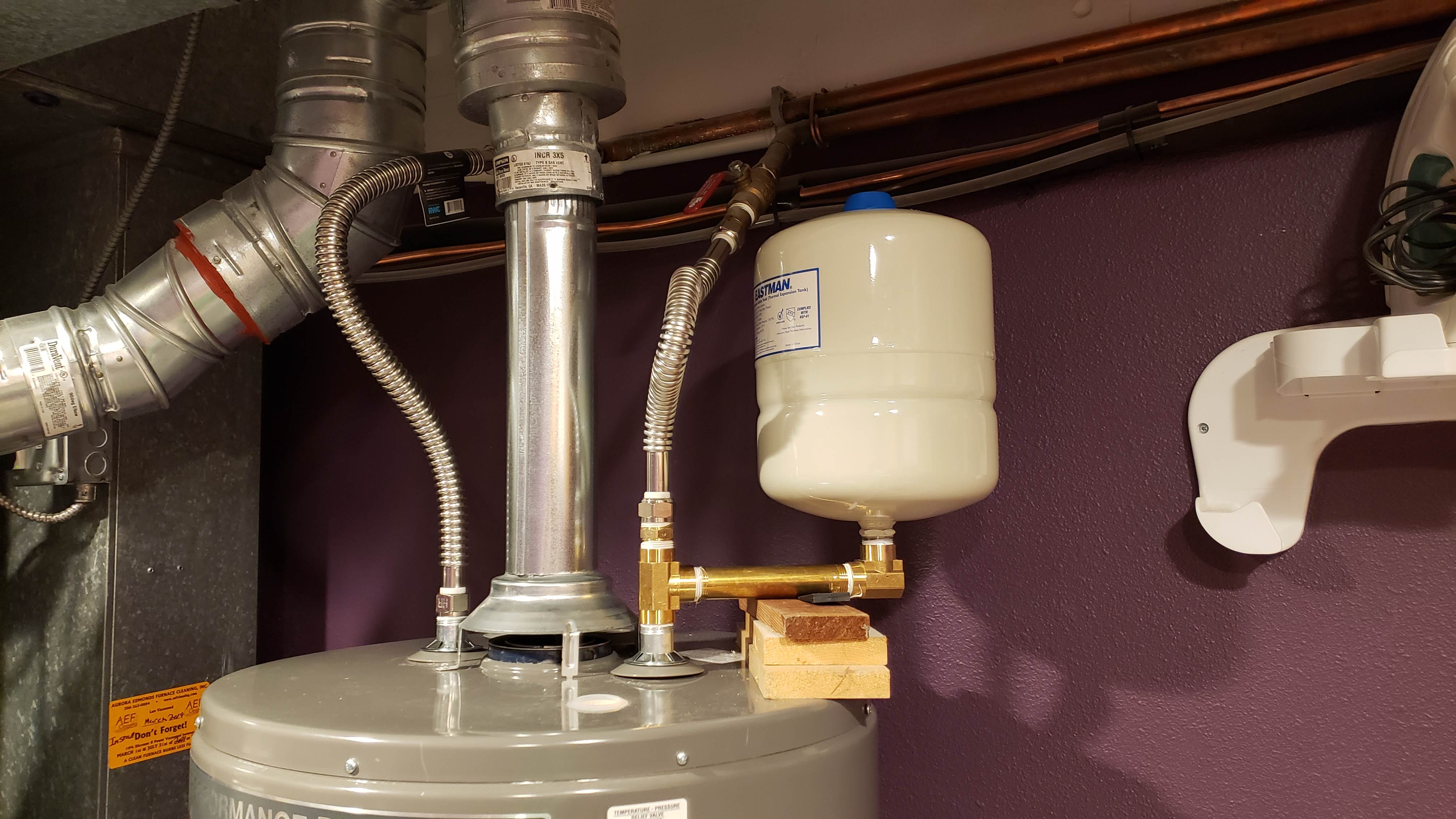

ONE last thing regarding the vent. If you look in the picture, they have that bend and then a short piece of what looks like the thin pipe just used for normal ductwork. I believe that should be a B-vent pipe there, right? I think I will be able to move the tank a little closer to the wall so a straight piece can go from the tank to that 3x5 reducer above without the bend above the tank. I saw some B-vent pipes at the store but they look pretty solid with finished ends. Are you able to cut those, or is there something else I need?

You are by code, allowed the single wall vent pipe AT THE HEATER

It can not be within 6'' of combustible surfaces

to finish the end of the single wall.

insert a piece of pipe in the vent on a 45 degree angle, and you can use that to bend a lip on the pipe

you need a crimping tool to crimp the other end to insert into the double wall B vent